Products:

• INDUSTRIAL SUPPLY

• INDUSTRIAL HOSE

• HYDRAULIC ADAPTERS

• HYDRAULIC HOSE

• TUBING

• GASKETS

• TESTING

• “O” RINGS

• FIRE HOSE

• METAL HOSE

• CYLINDERS

• DISCONNECTS

• Non-Asbestos

• Grafoil

• Sponge

• Sanitary

• Viton

• Foam

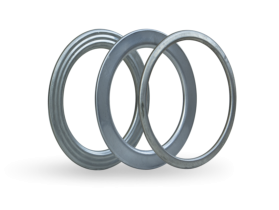

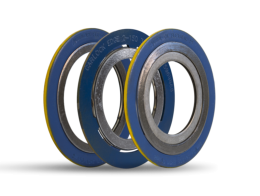

• Metallic

• Rubber

• PTFE

Non-Stock Requests

Need a gasket made from material we don't currently stock? We are happy to source additional

non-stocked materials for additional lead time and cost.

• Fibre Gasket

• Rubberized Cork

• Styrene Butadiene Rubber

• And many more

Contact us to discuss your options.

North American Hose and Fittings provides competitively

priced quality goods and excellent service to ensure your companies

business for years to come.

One of those products we supply is gaskets. North American

Hose and Fittings is a family owned business focused on providing

not only every day sealing needs, but also solving uniquely

challenging sealing problems for our customers needs.

Need a gasket? Call us today, let’s talk.

Combined industry experience of over 125 years!

North American Hose

6600 AIRLINE HWY

Baton Rouge LA, 70805

Ask a sales associate for assistance!

Gaskets

North American Hose and Fittings

Baton Rouge Louisiana 70805

“Specialist in metric hydraulic hose assemblies”

WE HAVE MOVED!

6600 AIRLINE HWY

Locally owned and operated!

Phone:

(225) 383-9213